|

New and Used Outboard motors for sale

Services / Other Services

Alabama, USA

|

|

|

Awesome Way to try and Increase Your Sales Immediately!

Services / Computer

Australia, Australia

|

|

|

Pug Puppies for sale | Pug Puppies for Adoption

For Sale / Animals - Pets

California, USA

|

|

|

Write Blog Posts - $35 an Hour

Jobs / Sales Jobs

USA

|

|

|

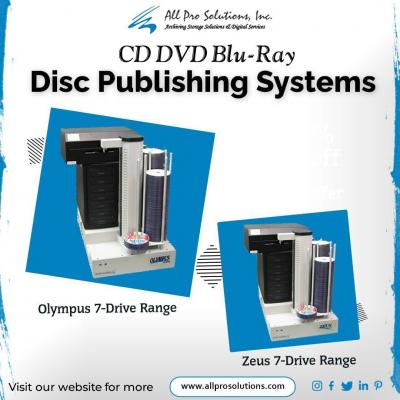

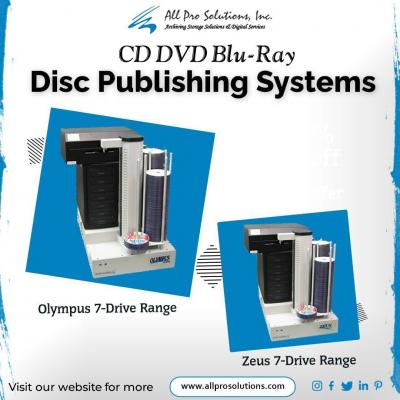

CD DVD and Blu-ray Disc Publishing Systems for Your Media Needs

For Sale / Electronics

South Carolina, USA

|

|

|

365 Day of Healthy Living

Miscellaneous / All Other Ads

Aus, Australia

|

|

|

Efficient and Reliable International Shipping with Lex Pack & Ship

Services / Other Services

New York, USA

|

|

|

Get a Gift Card Valued Up to $750 or Other Free Stuff!

Miscellaneous / All Other Ads

California, USA

|

|

|

App Development Company

Services / Other Services

California, USA

|

|

|

Move Out Cleaning Service Los Angeles

Business / Other

Culver City, USA

|

|

|

Shop Now for Your Unique Console Set

Services / Other Services

Santa Clara, USA

|

|